Initiatives and Case Studies

KMK Metals Recycling: Celebrating 45 years in business

KMK Metals Recycling are the industry leader in certified resource recovery solutions and play a crucial role in achieving Ireland’s ambitious recycling targets. As lead contractor to the largest WEEE compliance scheme WEEE Ireland, KMK Metals Recycling collect material from retailers and recycling centres throughout Ireland to treat both hazardous and non-hazardous materials at their facilities in Co. Offaly and Westmeath.

Partner Initiative / WEEE Ireland & Partners / All WEEE / Recycle

Key Findings

- KMK Metals Recycling employs approximately 150 staff across its operations, managing more than 48,000 tonnes of material and serving over 2500 sites including civic amenity sites, electrical retailers and Irish businesses.

- Over 200 million electrical items have been diverted from landfill during WEEE Ireland’s 18-year partnership between WEEE Ireland and KMK Metals Recycling in Co Offaly.

- Steel, plastic, and glass make up the top 3 materials extracted, with over 20,000 tonnes recovered annually.

- KMK Metals Recycling has won several awards at the Pakman National Environmental and Sustainability awards, the Tullamore Chamber awards and for its entries in the town’s annual St. Patrick’s Day parade.

- In 2024, KMK Metals Recycling became the first WEEE Recycling facility to become R2v3 certified. This is a global recycling standard, which ensures that companies adhere to environmental standards and data protection from certified electronics recyclers.

Top categories of e-waste recycled in 2023 (by weight)

| Large household appliances | 16,000 tonnes |

| Small appliances | 11,000 tonnes |

| TVs/Monitors | 3,000 tonnes |

Summary

KMK Metals Recycling was established in 1979 in Co. Offaly, Ireland. In 1985, KMK set up their first recycling facility in Tullamore. KMK provide a fully compliant collection and processing facility for hazardous and non-hazardous metals. KMK Tullamore (1.29 hectares) became the first WEEELABEX certified recycling facility in Ireland in 2015. This was followed by EN 50625 certification at their second licenced facility in Kilbeggan (1.7 hectares). KMK are responsible for the collection and processing of WEEE from retailers and recycling centres throughout Ireland on behalf of WEEE Ireland. KMK are also responsible for the collection of batteries from retail outlets, businesses and schools on behalf of WEEE Ireland. After processing at KMK, metals and plastic resources are safely packed and shipped to compliant dedicated facilities across Europe for further treatment.

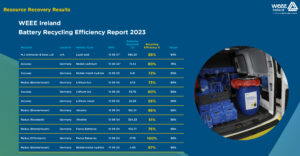

As the only dedicated waste battery sorting and management facility in Ireland, KMK have collected and segregated over 18,000 tonnes – the equivalent to nearly one billion AA batteries – on behalf of WEEE Ireland since they began working together under the European Battery Directive obligations in 2008. What others have designated as waste, KMK see this as a valuable resource, and work hard to get as much value and use out of this resource as possible.

More recently, KMK installed a STEINERT magnetic separation, eddy current and state of the art STEINERT KSS colour sorting system. The STEINERT project has revolutionized material extraction, culminating in the successful completion of a Small Domestic Appliances (SDA) recycling process initiated 12 years ago. The advancement involved deploying a Smasher and Shredding System, integrating a Trennso fines treatment, and re-engineering the Holman-Wilfley wash table. This comprehensive SDA recycling process now produces 99% clean plastics and metal fractions, fostering a truly circular system.

KMK also operate a zero waste to landfill policy and aim to eliminate the disposal of waste in landfills, focusing instead on waste reduction, reuse, recycling, and recovery. Biodiversity is very important to KMK. In 2022, KMK became an official All-Ireland Pollinator Plan (AIPP) Business Supporter and began following AIPP guidance on supporting and monitoring wildlife at KMK Kilbeggan site’s green areas and the local village. KMK’s first official opening of its biodiversity area occurred in 2023, The area is rich with biodiversity friendly native trees and shrub species such as willow, birch, hawthorn, holly and guelder rose.

Following on, , the Votechnik ALR4000 has found its home in KMK’s facilities. It is a unique piece of engineering; a self-contained plant for the processing of waste flat panel displays or FPDs. The ALR4000 depollutes the FPDs of the hazardous materials in a speedy process that allows the remainder to be shredded, quickly liberating the valuable material. The process is akin to keyhole surgery where the FPDs are scanned, and specific incisions made to target the liquid crystal glass panel and the cold cathode fluorescent tubes which contain hazardous substances. It is designed to process 60 FPDs per hour which is 20 times the capacity increase compared to manual labour. Its processing range includes 12”- 90” displays LCD TVs and PC Monitors. Processing over 45 tonnes of FPDs per week and achieving an overall recycling and recovery rate of 96.93% from their downstream sort and separation process, KMK Metals Recycling is leading the way to the circular economy.

Nearly all the materials KMK export are also treated in Ireland and the EU with 86% of material transported within a 500km radius of KMK Tullamore. Managing an energy intensive operation requires innovative thinking to mitigate against environmental, cost and supply risks. KMK Metals are now saving approximately 64,000Kg of CO2 per year across Tullamore and Kilbeggan, following a large-scale PV panel installation in 2022 and again in 2024. PV allows KMK to generate clean sustainable energy that prevent greenhouse gas emissions. These new panels generate approximately 46% of KMK’s energy needs, going a long way to support the recycling and recovery activity carried out on behalf of WEEE Ireland.

Green-house gas emissions have decreased relative to productivity over the last decade. Energy use per tonne has fallen by 14% since 2014 and CO2 emissions per tonne (scope 1 and 2) have fallen by 39%. With productivity increasing in 2024, KMK purchased their first EV forklifts for both sites. The transition from diesel to EV power is a significant milestone for KMK, reflecting both environmental and operational benefits.

Investment in quality and innovative e-waste recycling systems certified to EN 50625, such as those in place in KMK, are baseline requirements for efficient resource recovery and a more circular manufacturing economy. Critical raw materials recovery is fundamental for Europe’s sustainable technological transition.

For more information:

To find out more, please visit www.kmk.ie.

Or contact the WEEE Ireland team at info@weeeireland.ie